Exploring the Transformative Power of Laser Processing In The Steel and Metals Industry

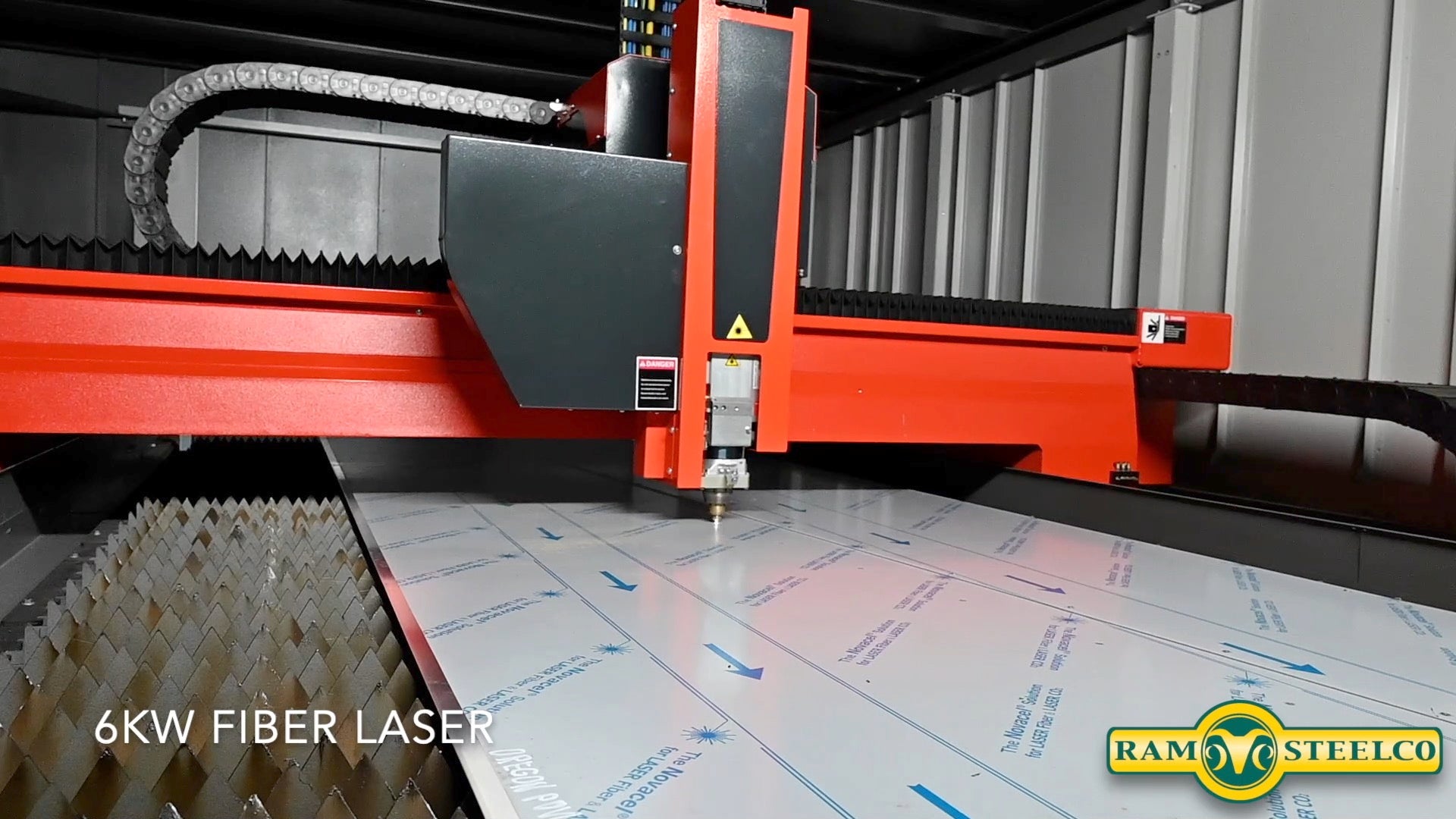

In the realm of modern manufacturing, precision is paramount. Every intricate detail matters, every cut must be flawless, and every mark must be indelible. This pursuit of perfection has led to the rise of laser processing in the steel and metals industry, a revolutionary technology that has forever changed the landscape of manufacturing.

WHAT ARE THE BENIFITS TO LASER PROCESSING?

- Precision : At the heart of laser processing lies unparalleled precision. Unlike traditional methods such as mechanical cutting or engraving, laser processing harnesses the focused energy of a highly concentrated beam of light to achieve microscopic accuracy. This precision allows for intricate designs, complex geometries, and immaculate finishes that were once deemed impossible.

- Versatility Unleashed: One of the most remarkable aspects of laser processing in the steel and metals industry is its versatility. From cutting and engraving to marking, the applications of laser processing are virtually limitless, empowering manufacturers to explore new frontiers and push the boundaries of what's possible.

- Efficiency Redefined:In addition to its precision and versatility, laser processing also delivers unparalleled efficiency. By eliminating the need for tool changes, reducing setup times, and minimizing material waste, laser technology streamlines production processes and boosts overall productivity. This efficiency not only saves time and resources but also lowers costs.

- Quality Assured: In the pursuit of innovation, quality should never be compromised. Laser processing upholds the highest standards of quality, delivering consistent, reliable results with every operation. With advanced monitoring systems and stringent quality control measures, manufacturers can trust in the integrity and durability of laser-processed components, ensuring customer satisfaction and long-term success.

- Embracing the Future: As we stand on the cusp of a new era in manufacturing, laser processing emerges as a beacon of progress and possibility. Its precision, versatility, efficiency, and quality make it an indispensable tool for industries ranging from aerospace and automotive to electronics and healthcare. By embracing laser technology in the steel and metals industry, we can unlock new opportunities, drive innovation, and stay ahead of the curve in an ever-evolving marketplace. Laser processing is more than just a technological advancement—it's a revolution. It's redefining the way we manufacture in the steel and metals industry, pushing the boundaries of what's possible, and shaping the future of industry. As we continue to harness the transformative power of laser technology, the possibilities are truly limitless. So let's embrace this precision revolution and embark on a journey of innovation together.

Ram Steelco is at the forefront of laser processing in the steel and metals industry , offering a comprehensive range of services to meet your manufacturing needs. Contact us today to learn more about how we can elevate your next project tand let's shape the future of manufacturing in the steel and metals industry.

CALL US TO DISCUSS YOUR NEXT PROJECT!

Stay connected with us on social media for industry insights, project showcases, and exclusive offers!

Learn About All Our Capabilities

- Laser Cutting

- Forming

- Hy-Def Plasma

- Rebar Processing

- Rolling

- Saw Cutting

- Shearing

- DXF & PDF Conversion